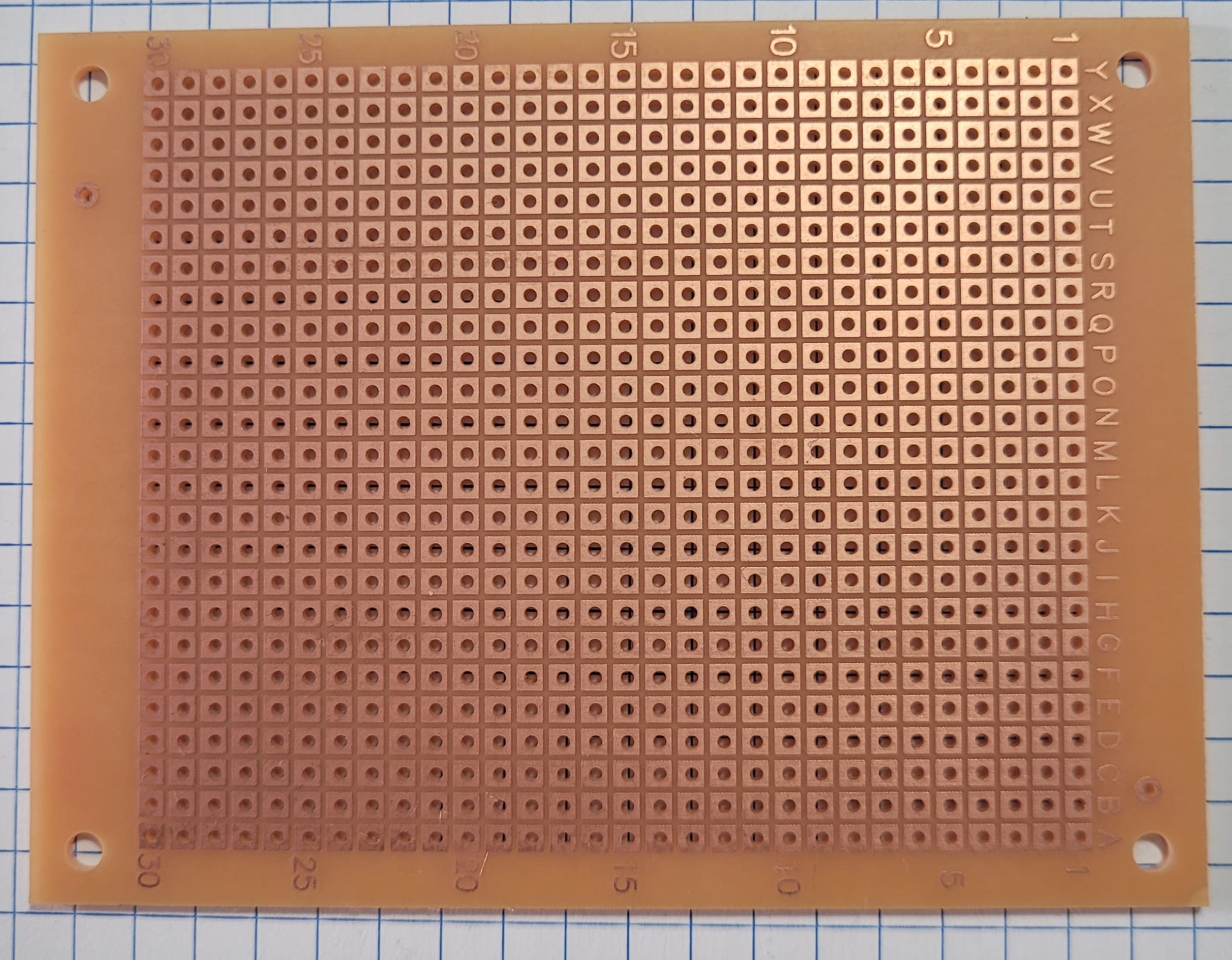

This week was marked by several key developments. Last week, the electrical circuit for the chest device (RP2040) was developed. However, when attempting to design the corresponding PCB, the team members responsible concluded that they would not have enough time to complete this task without compromising their other responsibilities.

There was also significant difficulty in maintaining the intended dimensions for certain PCB components while adhering to the requirement of using only a single layer. This constraint would have required changes to the physical circuit connections, which, at this advanced stage of the project, proved impractical.

Given this situation, the team decided to use a protoboard (soldering/experimentation board), which, although it does not allow for a reduction in circuit size, proved to be a more practical and safer solution. This choice also helped avoid the risk of the custom PCB not functioning correctly on the first attempt.

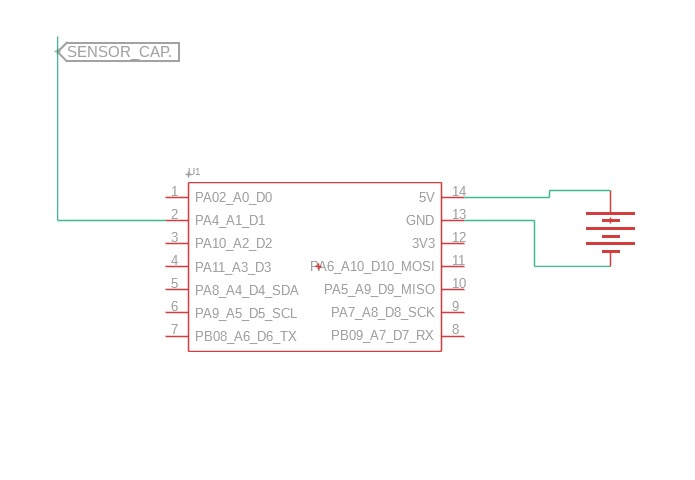

At this point, the capacitive sensor is fully operational, and the Bluetooth connection issues with the RP2040 board have been resolved. This Friday marked the second visit to the factory of the company with which we are collaborating. In discussions with the company representatives, it was concluded that part of the capacitive sensor circuit could be integrated into the earmuff structure.

The company kindly provided a sample earmuff, similar to those used by their workers, so we could determine the internal organization of the circuit. During this visit, the third and final visit to the factory was also scheduled for June 6th at 3:00 p.m.

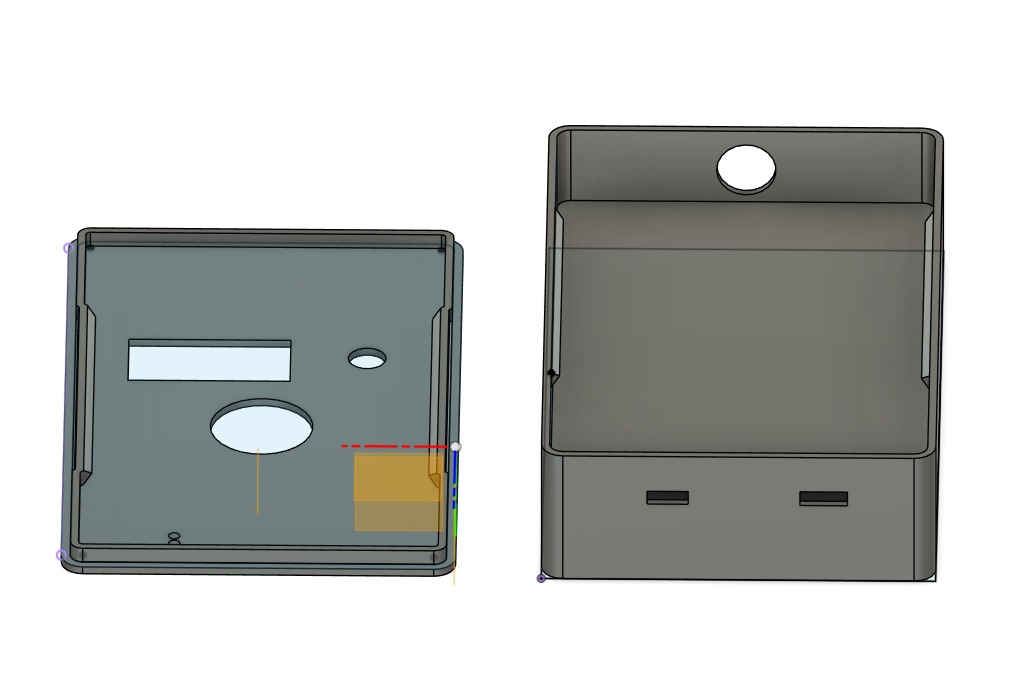

The 3D modeling of the enclosures that will house the developed devices also began this week. The team members responsible for this task have, up to this point, been learning how to use Autodesk Fusion 360, the software recommended by the instructors. The enclosure for the noise detection and alert system is nearly complete, with only a few details remaining—specifically, how to secure the protoboard inside the box and how to position the holes for the LEDs, display, and charging ports. To address this, three team members will meet next Tuesday to solder the circuit and take the necessary measurements for any required adjustments.

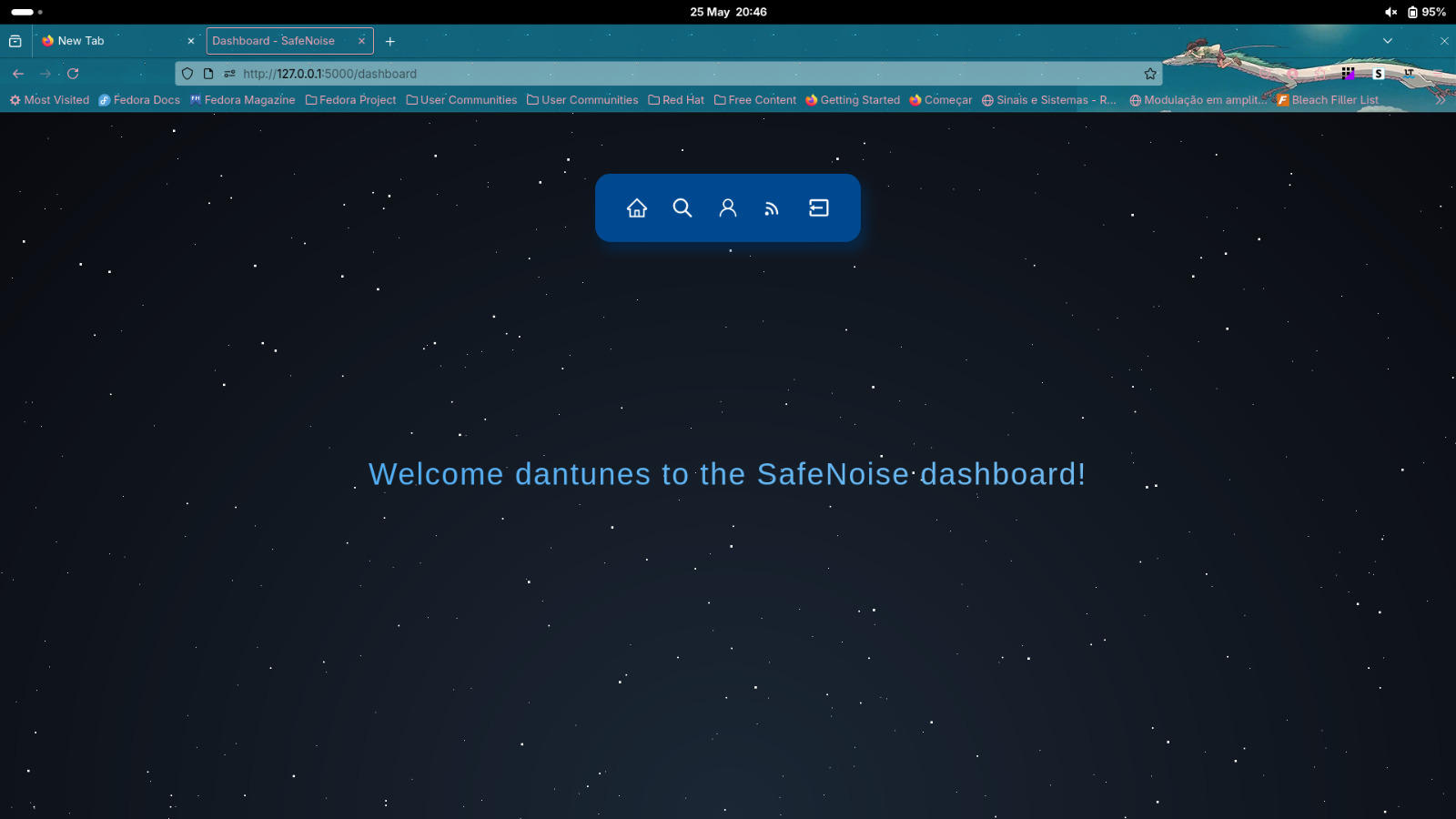

The data reception and storage platform was also completed this week. It is now possible to search and analyze information from different users. The scalability of the application was improved, with several bugs related to login, logout, and navigation between website sections being resolved, resulting in a smoother user experience.

Finally, the schematic for the capacitive sensor circuit was completed. In addition, the team began discussing possible ideas for the project presentation video. Some team members also started preparing the final presentation of the project work.