EU-funded projects: participation

1. ECCO Project (2017-2021)

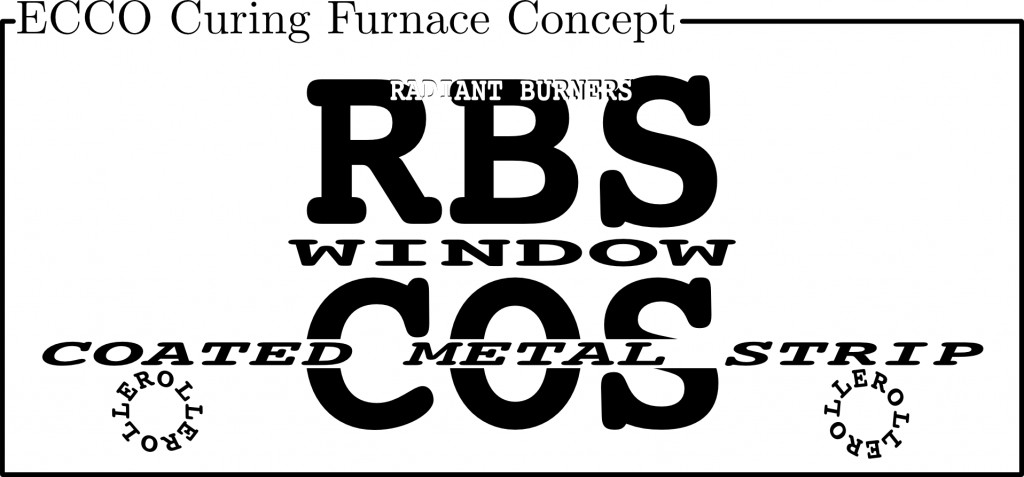

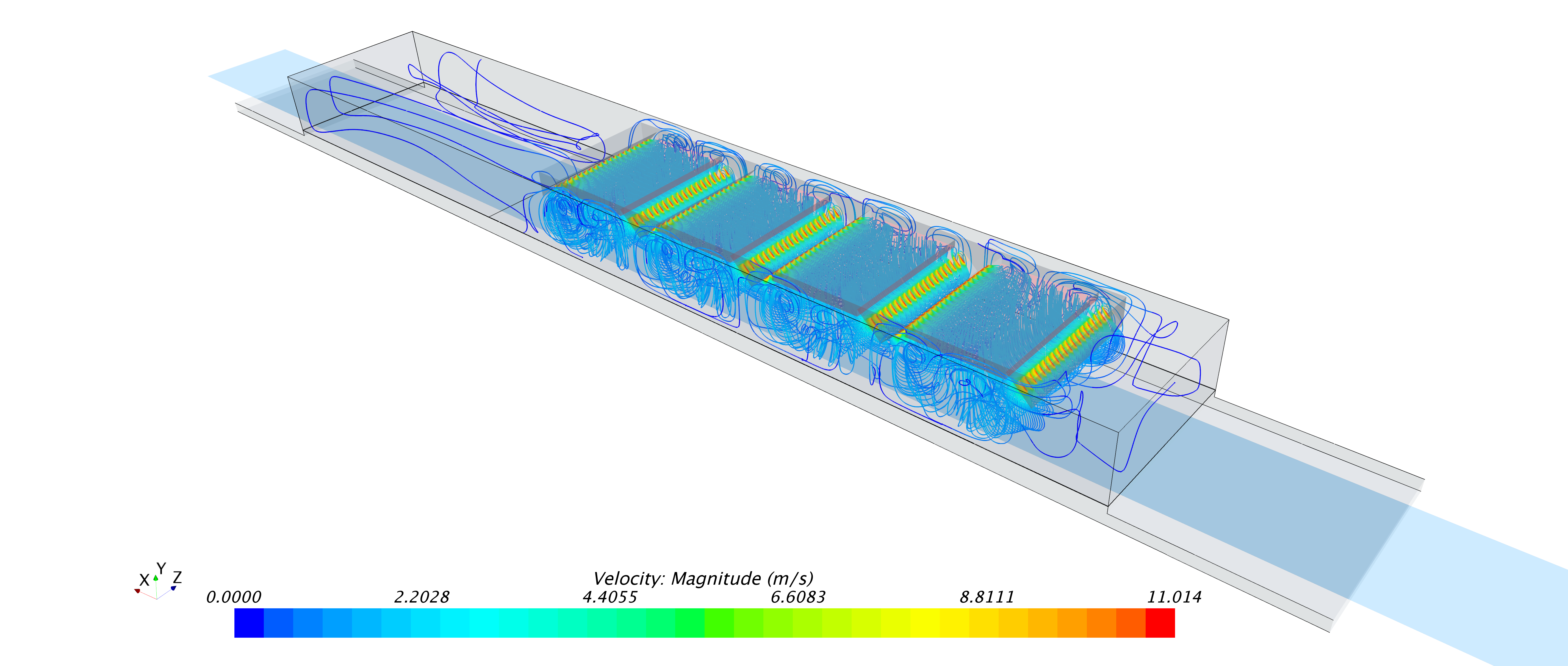

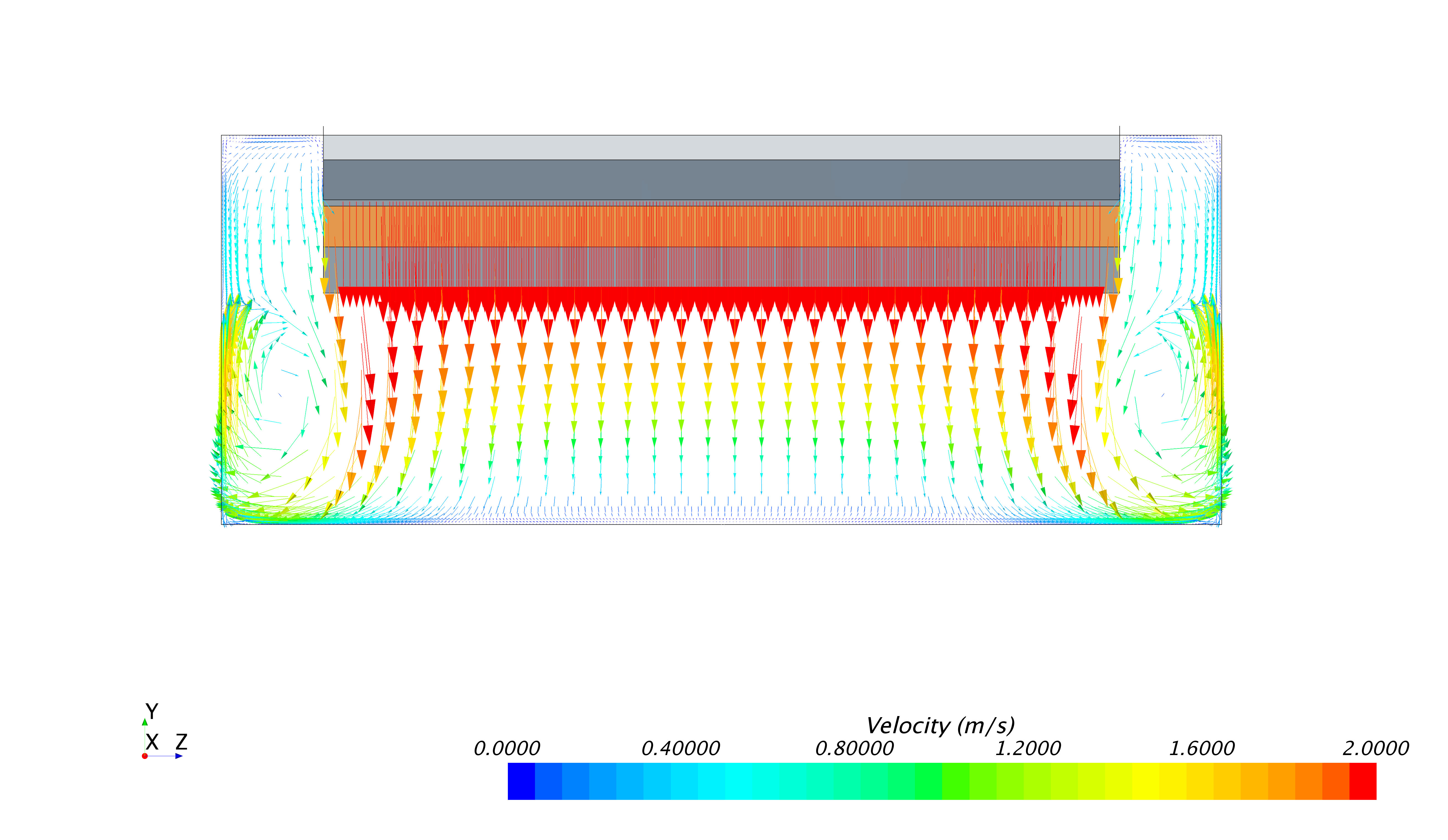

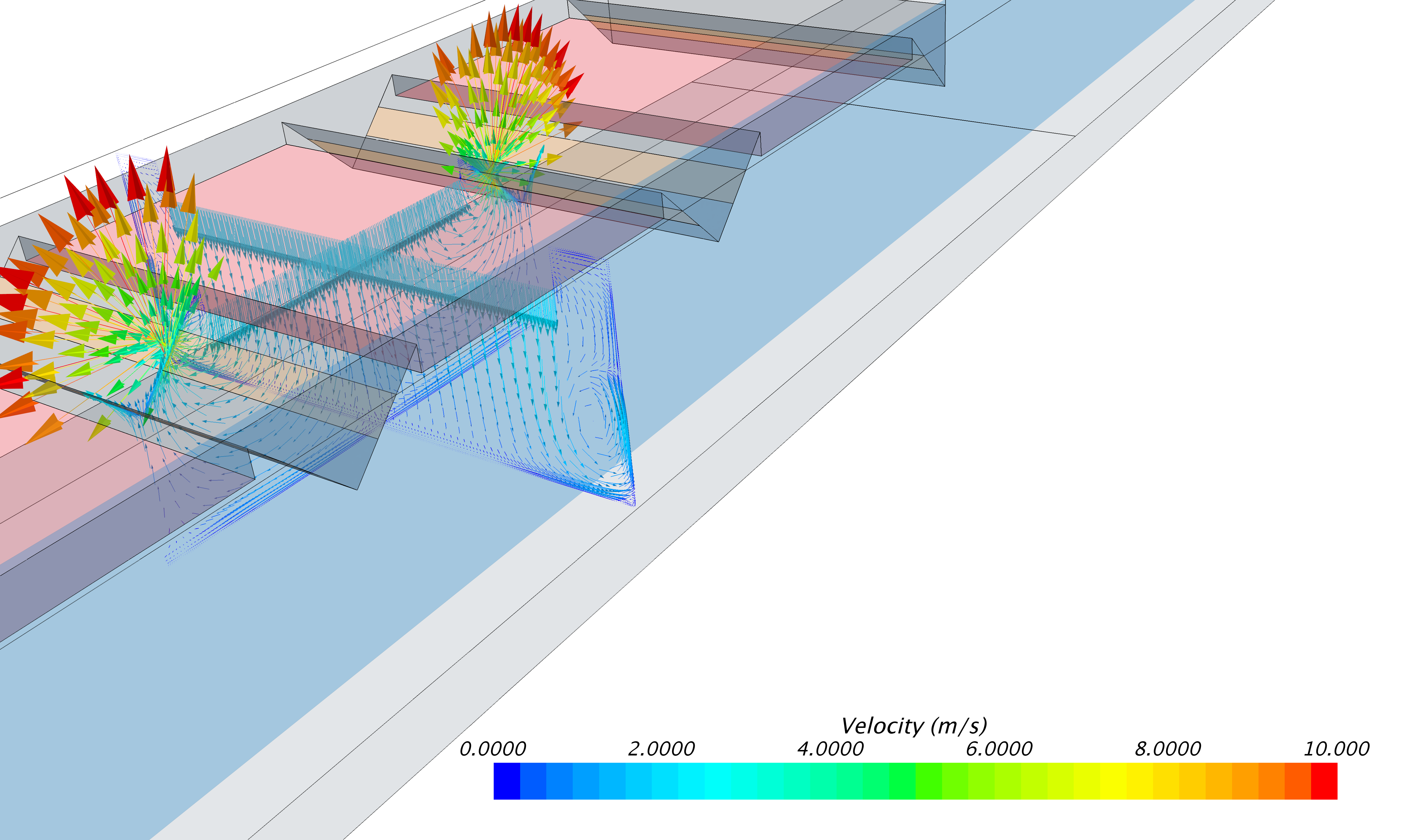

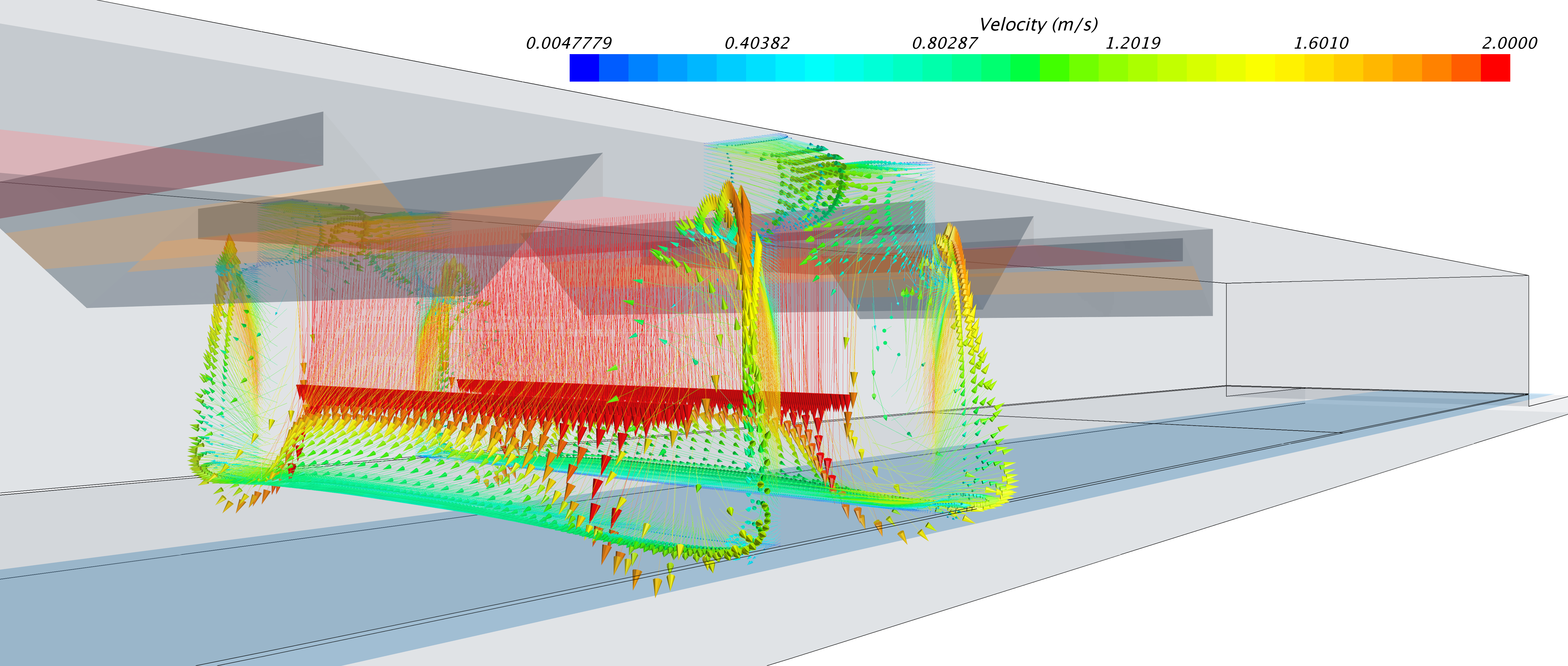

The ECCO project aims at developing an innovative furnace for drying and curing organic paints that are commonly applied on the surface of metal coils for protective and decorative purposes. The proposed coating drying/curing concept does not rely on the traditional convective air drying technology. Instead, the energy required for driving the overall thermochemical processes in the coating is delivered to it through radiative heat transfer from radiant burners that are fed with previously evaporated solvents. To comply with such requirements, the ECCO curing furnace is composed by two main regions that communicate directly with each other exclusively through heat transfer. These regions are herein termed as the radiant burner section (RBS) and curing oven section (COS). The figure provides a simplified representation of the curing furnace concept depicting the furnace main regions and components (identified by the corresponding names) as well as the relative position between them.

The COS is continuously fed with a coated metal strip. The RBS provides the heat source – IR- radiation emitted from radiant porous burners – to execute the coating drying and curing processes that take place at the COS. Along the residence time of the coated coil within the COS, the coating (wet paint) needs to be dried and cured to meet the required standards. The released toxic solvent species are collected from the COS and guided towards the radiant burners feeding system in order to, simultaneously, incinerate the solvent species and decrease or eliminate the fraction of natural gas required. The radiant burners are placed at the ceiling of the RBS to promote high radiative heat transfer rates from the emission source (porous media) to the coated metal stip. These burners are developed to maximize the radiant power fraction over the advective heat transfer contribution from the released combustion energy. In order to guarantee the separation between the atmospheres of both sections while simultaneously supporting the radiative heat transfer coupling between sections, a window made out of a highly transparent glass is applied in between both regions.

2. FC-District Project (2010-2014)

The overall objective of the FC-DISTRICT project is to optimize and implement an innovative energy production and distribution concept for sustainable and energy efficient refurbished and/or new “energy autonomous” districts exploiting decentralized co-generation coupled with optimized building and district heat storage and distribution network. The concept is based on dynamic heat exchange between the building(s) (fitted with Solid Oxide Fuel Cells (SOFCs) for energy production collaborating with improved thermal storage and insulation building systems), the distribution system (optimized piping and district heating with or without a heat buffer) and the consumer (new business and service models), aiming to achieve energy balance at district level. Advanced insulation materials will be developed and implemented for the improvement of building and pipe thermal response. The energy reduction will originate from improved efficiency and cost effective high temperature (SOFC), to act as micro heat and power cogeneration (μ-CHP) systems providing demand-flexible electricity and heat to the building and district, coupled with optimised energy and power distribution networks that will optimally control heat storage at building and/or district level. FC-DISTRICT integrates a proven innovative mid-term energy technology (SOFC) with heat management at building and district level (building thermal storage coupled with intelligent distribution networks) to serve the consumer needs for economy-ecology-sustainability. It introduces a new paradigm in energy efficiency by developing materials, technologies, methodologies and systems specifically intended for integration at district level.

1. FCT Project – “Multi-scale prediction of methane reforming under microwave heating”. Submitted on January 2015

2. FCT Project – “An innovative hybrid particle-continuum method for multi-scale transport in porous media”. Submitted on May 2017