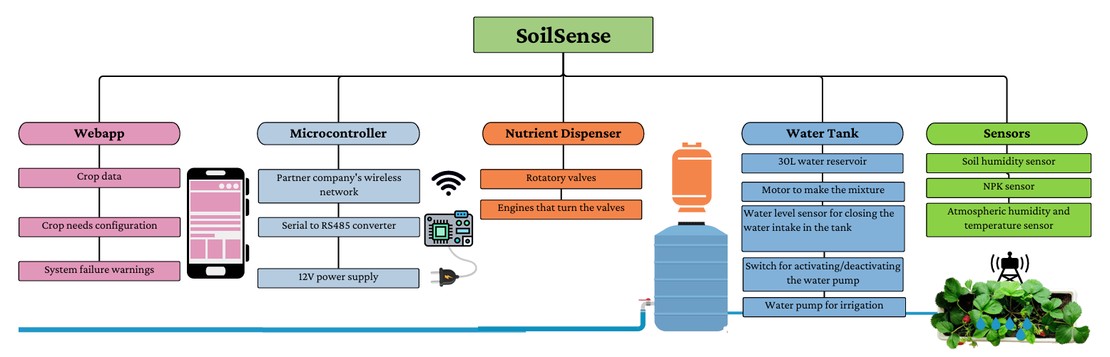

WebApp

Save and process the crop data

Data base

Stores all crop-related data securely, including sensor readings, crop configurations, user information, and historical irrigation logs. Enables efficient data retrieval and scalability.

Web Interface to Input and Manage Crop Data

A user-friendly frontend interface that allows farmers or administrators to enter new crops, view details, edit configurations, and monitor real-time or historical data.

Association Between Crop and Sensor Zone

Links each crop entry to a specific sensor zone, allowing the system to collect and process only relevant environmental data for that crop. Enables precise, zone-based automation.

Historical Data Logging & Visualization

Maintains a history of environmental conditions, irrigation events, and nutrient dispensing. Frontend charts and logs help users evaluate crop health and system effectiveness over time.

System failure warnings

Sends alerts (web notifications) when crop conditions go outside the defined thresholds or if scheduled irrigation is missed.

Microcontroller

Connect and control all hardware components for monitoring and automation

Microcontroller Unit

Central processor responsible for handling sensors, actuators, and communication with the webapp.

Power Supply – 12V Adapter

Provides stable power to the entire system. Ensures reliable power delivery for sensors, actuators, and communication modules.

RS485 Serial Communication Converter

Enables long-distance and robust communication between the microcontroller and industrial-grade sensors or actuators using the RS485 protocol. Converts UART serial signals to RS485 differential signals.

Wireless Connectivity

Connects the microcontroller to the partner company’s wireless network, allowing real-time communication with the backend (e.g., to send sensor data, receive commands, or update firmware remotely).

Actuator Control

Sends signals to actuators based on control logic:

1. Relay Module: Turns the water pump on/off

2. Motor Drivers or MOSFETs: Control mixing motors and rotatory valves

Local Logic & Scheduling

Compares real-time sensor data with thresholds to trigger irrigation or mixing actions.

Manages timing for periodic irrigation.

Nutrient dispenser

Dispense nutrients automatically according to crop needs

Rotatory Valves Electrically controlled rotary mechanisms that open/close nutrient flow paths for precision dosing.

Engines that Work Like Valves Small motors or actuators that regulate the release of nutrient solutions. Controlled via the microcontroller.

Nutrient Mixing Logic Uses predefined crop settings (e.g., NPK ratios) to calculate how long and which valves to open.

Water Tank

Store and manage water for irrigation

30L Water Reservoir

Storage unit for irrigation water. Can be manually or automatically refilled.

Water Pump for Irrigation

Pumps water from the reservoir to the crop zone. Activated via relay or transistor switch.

Motor to Make the Mixture

Agitates the contents of the tank to ensure uniform mixing of nutrients and water.

Water Level Sensor

Detects when the tank is full. Used to prevent overflow by stopping intake.

Relay for Pump Activation

Electrically isolates and controls the water pump. Can be triggered by the microcontroller based on sensor input or scheduling.

Sensors for the Work Environment

Monitor environmental and soil conditions

Soil Humidity Sensor

Detects the moisture level in the soil. Essential for determining when irrigation is necessary. Usually provides analog output for fine-grained readings.

NPK Sensor

Measures the concentration of nitrogen (N), phosphorus (P), and potassium (K) in the soil. Communicates via UART or RS485. Helps tailor nutrient delivery to the crop’s specific needs.

Atmospheric Humidity and Temperature Sensor

Tracks ambient air temperature and humidity. Useful for climate monitoring and optimizing greenhouse or open-field conditions. Common models include DHT22, BME280 (digital, I2C/SPI).