TECHNOLOGY PLATFORM ON MICROENCAPSULATION AND IMMOBILIZATION

TPMI

TECHNOLOGY PLATFORM ON MICROENCAPSULATION AND IMMOBILIZATION

Provide a technical solution for the most varied challenges in product development, through the development of customized microcapsules and microscaffolds (MICROSCAFS), creating value to industrial partners and leading to breakthroughs at the scientific and technological level.

A Technology Platform consists on a basic technology that is modified each time to address new challenges.

The Technology Platform on Microencapsulation and Immobilization deals with customized functional microparticles (microscaffolds) or microcapsules, either with hybrid composition, or with hybrid performance. Their custom-tailored morphology, porosity and organic functionality enable the entrapment and/or grafting of a variety of chemical species.

The microcapsules exhibit a controlled release of a specific chemical at a target moment, or condition. The “loaded” matrices (microscaffolds) can be used not only for an application where a slow release of the entrapped compound is needed, but also for an application in which the compound loss is unwanted, i.e. an anchored active chemical is desired.

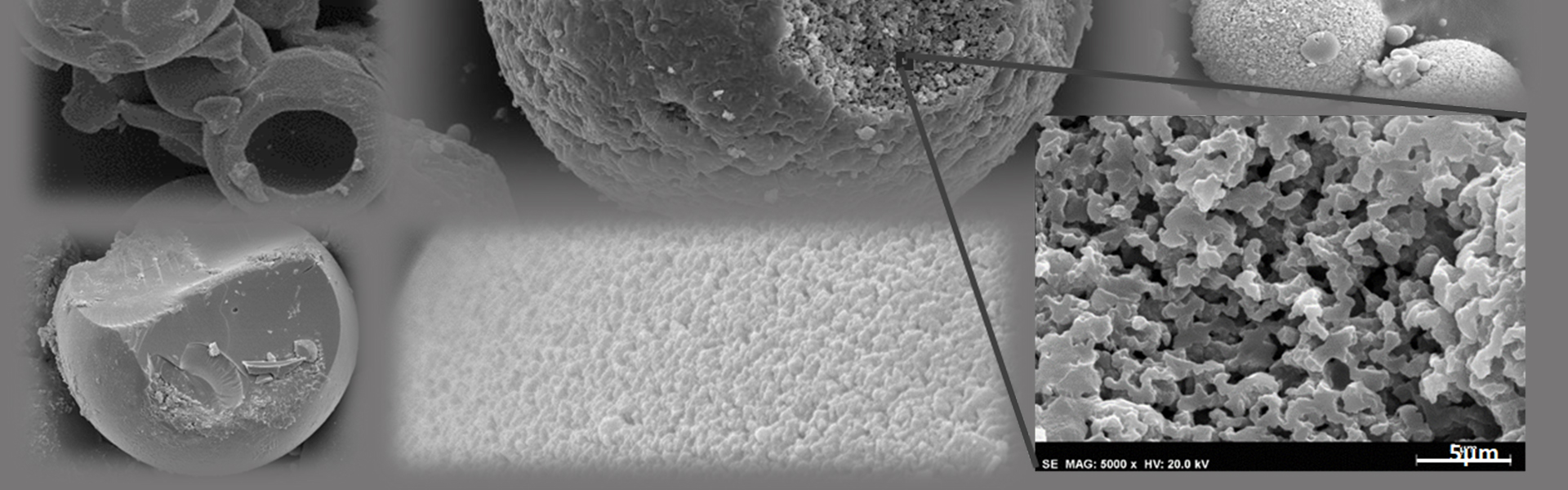

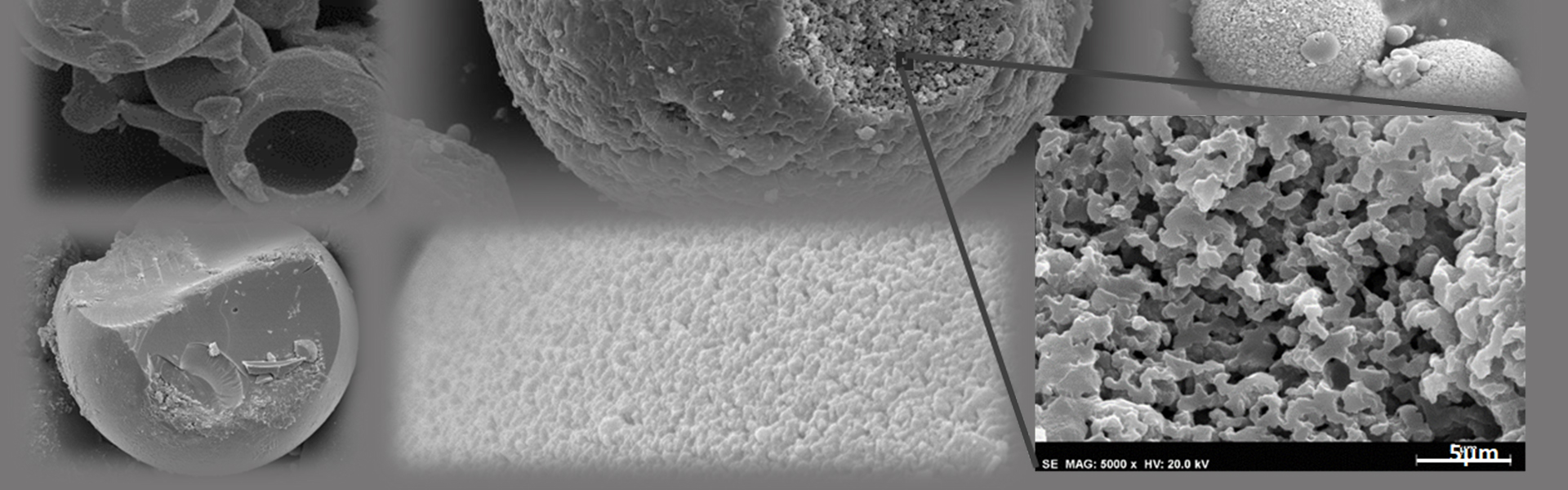

… different morphologies for varied applications …

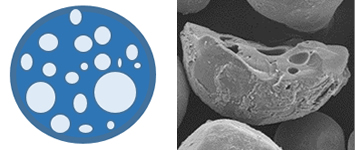

Mesoporous continuous matrix entrapping the active compound

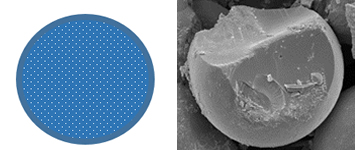

Meso and macroporous matrix to entrap active compounds

… hybrid composition … entrapment of a variety of chemical species ...

water

glycols (polyols)

biocides

amines

flame retardants

isocyanates

silanes

essential oils or fragrances

etc.

…other chemical and biological species…

Silica and multicomponent oxides

Organically modified silica

Silica / epoxy

Silica / cork

Silica / PDMS

Silica / PTFE

Polyurethane, Polyurea

Low melting point polymers

…other polymers…

Active compounds release (diffusion, convection, desorption,…)

By contact, synergy,…

Mechanical pressure

Pressure change

Temperature

pH

…other stimulus…

Polymerization-Induced Phase Separation within Microspherical Domains

Biocide entrapment within microscaffolds for new anti-fouling coatings

Functional microcapsules for ecological and high performing polyurethane one component foams

Microscaffolds loaded with essential oils for slow perfume release

Encapsulated isocyanate for one component adhesives

Immobilization of photocatalytic titania nanoparticles into MICROSCAFS

Project ECOBOND: Development of new autoreactive and ecological monocomponent adhesives

Project NANOPOLI: Development of flame resistant nanocomposite

Project ELASTOMREG: Vulcanized thermoplastic elastomer with self-healing properties

Project SOLAR2CLEAN (PTDC/EQU-EQU/1056/2020): Engineered solar light driven photocatalytic systems for wastewater purification

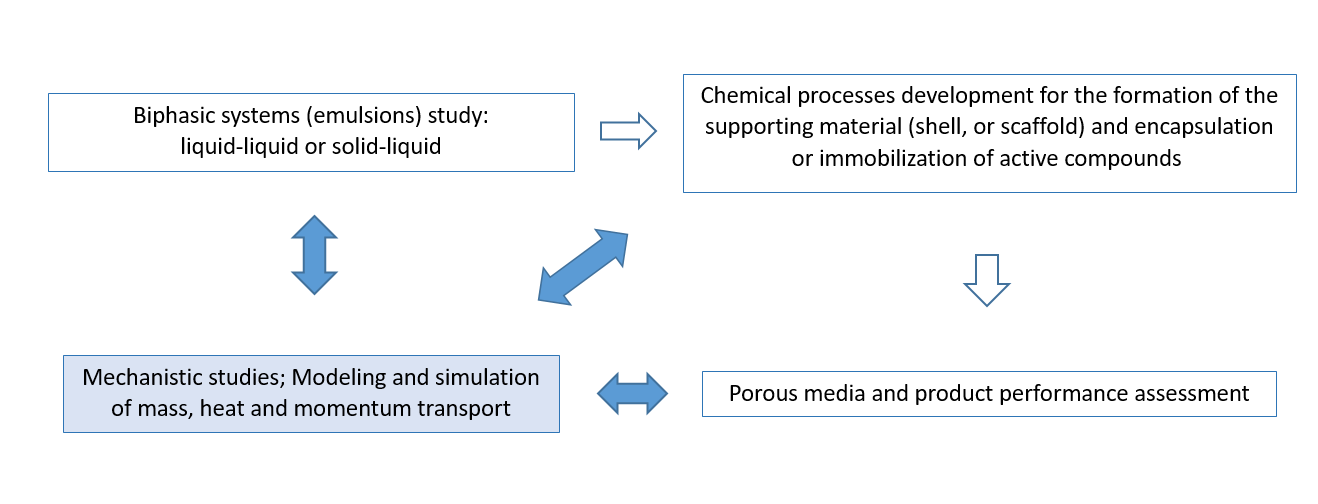

Our aim is to create the knowledge base needed to support the ever expanding range of applications. The Platform focuses on deepening the understanding of multiphasic systems (emulsions) stability, reaction engineering, processing and material properties and deals with the implementation of new methods and methodologies to support the development of microcapsules/microscaffolds with customized properties, able to address the industry needs in product development.

Collaborating with us is a cost-effective way for companies to meet their on-going research needs, while, at the same time, addressing challenges that extend beyond their individual research and innovation portfolios. By letting us know your product and process specifications, we will identify the most appropriate core-shell system, particle morphology and fabrication strategy. You just need to email us at ana.marques@tecnico.ulisboa.pt, in order to evaluate the feasibility of the work.

University and companies can jointly work on research topics of common interest, both within and across value chain segments. Private funding, as well as public national and international funding schemes may be employed.

This gives companies the opportunity to accelerate innovation and increase sustainable competitiveness and Universities the opportunity to apply basic and fundamental knowledge to contribute to the economy growth.

Some of the areas where we can play a role:

The innovative materials developed in the framework of this Technology Platform address new product development projects that foster a sustainable and cleaner environment, economic growth, people safety and the creation of innovation and knowledge-driven jobs. Research activities are carried out in close contact with industrial partners and technology is transferred accordingly.

Ph.D. Student

Ph.D. Student

Ph.D. Student (in collaboration with Prof. Fátima Montemor)

Ph.D. Student (in collaboration with IPLeiria - Profs. Florindo Gaspar and Artur Mateus)

The project SOLAR2CLEAN - Engineered solar light driven photocatalytic systems for wastewater purification (PTDC/EQU/EQU/1056/2020) was accepted for funding. It will run from Feb 2021 to Feb 2024.

Read MoreCongratulations to Maria, Patricia and Brenda who graduated, in Jan 2021, with the following M.Sc. theses:

"Microencapsulation of a Fragrant Oil with biodegradable polycaprolactone assisted by supercritical fluids", by Maria Terrucha. Supervised by Ana C. Marques and Miguel Rodrigues, at IST, in collaboration with SYMRISE SA"

"Porous silica microscaffolds for nanoparticle immobilization", by Patricia Silva. Supervised by Ana C. Marques.

" Isocyanate microcapsules loaded onto a TPE polymer matrix", by Brenda Silva. Supervised by Ana C. Marques, in collaboration with CABOPOL SA

Read MoreMonica V. Loureiro, Mario Vale, Rui Galhano, S. Matos, Joao C. Bordado, Isabel Pinho, Ana C. Marques, “Microencapsulation of Isocyanate in Biodegradable Polycaprolactone Capsules and Application in Monocomponent Green Adhesives“, ACS Applied Polymer Materials 2 (2020) 11, 4425

Congratulations to Ana Rita, Daniela, Catarina and Joana who graduated, in 2019-2020, with the following M.Sc. theses:

"Functionalization of Lignin Nanoparticles", by Ana Rita Alves. Supervised by Ana C. Marques and Anton Friedl (University of Vienna, Austria).

"Synthesis and Characterization of Nanocrystalline Transparent Conductive Oxides for Photocatalytic Applications", by Daniela Patricio. Supervised by Ana C. Marques and Alessandro Martucci (Universita degli studi di Padova, Italy).

"Bio-derived Films for Food Packaging", by Catarina Fernandes. Supervised by Ana C. Marques and Jorge Oliveira (University College Cork, Ireland).

"Development of bio-based films from seafood waste", by Joana Morais. Supervised by Ana C. Marques and Jorge Oliveira (University College Cork, Ireland).

Read MoreCERENA, Departamento de Engenharia Química, Instituto Superior Técnico, Universidade de Lisboa, Avenida Rovisco Pais, 1049-001 Lisboa, Portugal

Ana Marques´s Group, South Tower, Office 10.6.14, Phone: +351 218 417 335, ana.marques@tecnico.ulisboa.pt