Industrial Automation Course at ULisboa

PLC Digital Signals Oscilloscope

2025 José Gaspar

Introduction

This webpage has the purpose

of providing one coding example where one PLC stores samples of digital signals

in its memory and those signals are displayed by a remote PC within a time

evolving window. The display is realized with a Matlab function, running in the

PC, that uses the ethernet connection to poll the memory of the PLC. The

connection protocol is Modbus.

Requirements

This implementation

of the digital signals oscilloscope assumes it is installed the Modbus Matlab

interface as provided by the Industrial Automation Course at ULisboa.

Unity

Pro and Matlab

Download

the Unity Pro project stored in the zip file

and unzip

it. After downloading and unzipping the project, compile and transfer the

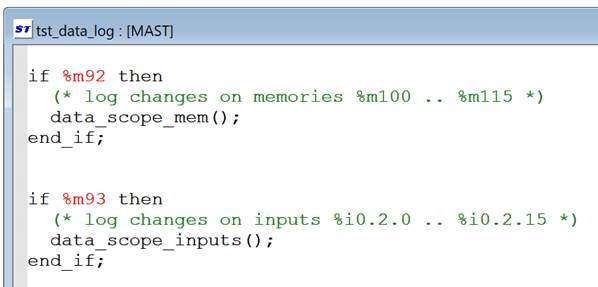

project to a simulated PLC (part of Unity Pro). In this PLC program, to have

digital signals saved in the PLC memory one needs to set true variable %m92,

see Figure 1.

|

(a)

Variable

%m92 needs to be set 1 in order to have data logging. |

|

|

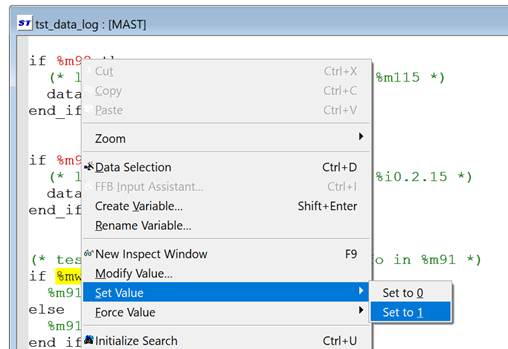

(b)

Set

the variable with a right click. |

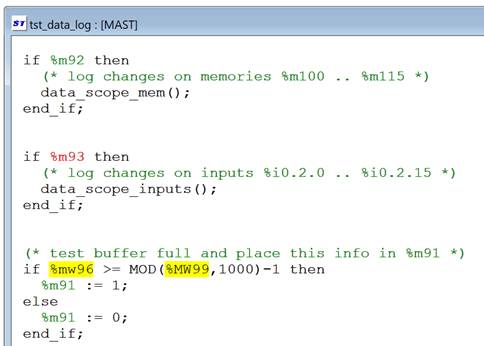

(c) Note

%m92 has a green color indicating it is set. |

|

Fig.1:

Logging of digital signals has to be enabled, as otherwise those signals will

not be visible using Modbus. |

|

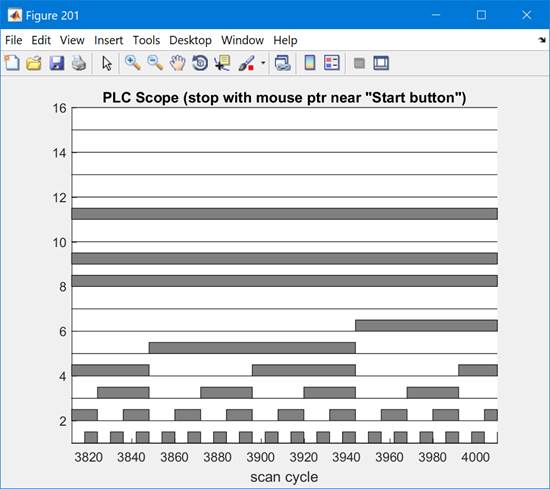

Having the

PLC running its code and saving data in memory to be accessed with Matlab, then

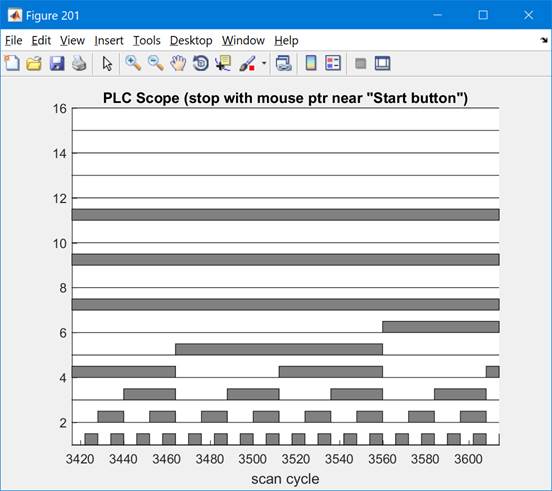

one runs the Matlab function data_scope_show.m. to display time evolving digital signals as

saved by the PLC. Figure 2 shows signals created by the PLC program. In this

example the PLC is counting using a decimal variable and that decimal variable

is interpreted as a collection of 16bits. Each bit is displayed along a time

window.

|

(a) Scan cycles 3410 - 3620, approx. |

(b) Scan

cycles 3810-4010, approx. |

|

Fig.2:.Two

different time windows (a, b). The counting in (b) is higher as shown by eight

bit which is ON now and was OFF before. |

|

Both the

PLC and Matlab run circular buffers to keep constant the memory usage and

approximately constant computational requirements from the beginning.

Maintenance

The

software offered on this webpage was created for the purpose of being used in

classes. There is no continuous maintenance other than the requirements

associated to the classes.

This

program is distributed in the hope that it will be useful, but without any

warranty; without even the implied warranty of merchantability or fitness for a

particular purpose.

Acknowledgment

In

case you find this software useful and do any publication in the sequel please

refer to the course Industrial

Automation at Instituto Superior Técnico, Universidade

de Lisboa, Portugal.

Contact

|

Prof. José Gaspar Instituto de Sistemas e Robótica, Instituto Superior Técnico, Torre Norte Av. Rovisco Pais, 1 1049-001 |

Office: Torre Norte do IST, 7.19 |