Welcome to my personal academic web page. My name is Jorge Navalho and here you can find some relevant information about my scientific and pedagogical work.

I hold MSc and PhD degrees in Mechanical Engineering from Instituto Superior Técnico, Universidade de Lisboa (IST-UL).

I was an invited assistant at the Mechanical Department of IST-UL lecturing: (i) Heat Transfer; (ii) Thermodynamics and Transport Phenomena; (iii) Thermal Equipments; and (iv) Advanced Heat Transfer — see Teaching.

My research interests comprise: (i) solar thermal and thermochemical energy applications; (ii) hydrogen production through reforming technologies; (iii) combustion and partial oxidation in inert and active (catalytic) porous media; (iv) heat and mass transport and reaction modelling and simulation in meso- and macro-porous structures and porous media; (v) pore-scale direct numerical simulations in porous media; and (vi) evaporation of solvent species in paint coating layers.

Publications

Peer Reviewed Articles

Bruno A. C. Barata, Jorge E. P. Navalho, and José C. F. Pereira. Prediction of Self-Sustained Oscillations of an Isothermal Impinging Slot Jet. Fluids. 8:15, 2023. [PDF] [BIB] [PUB]

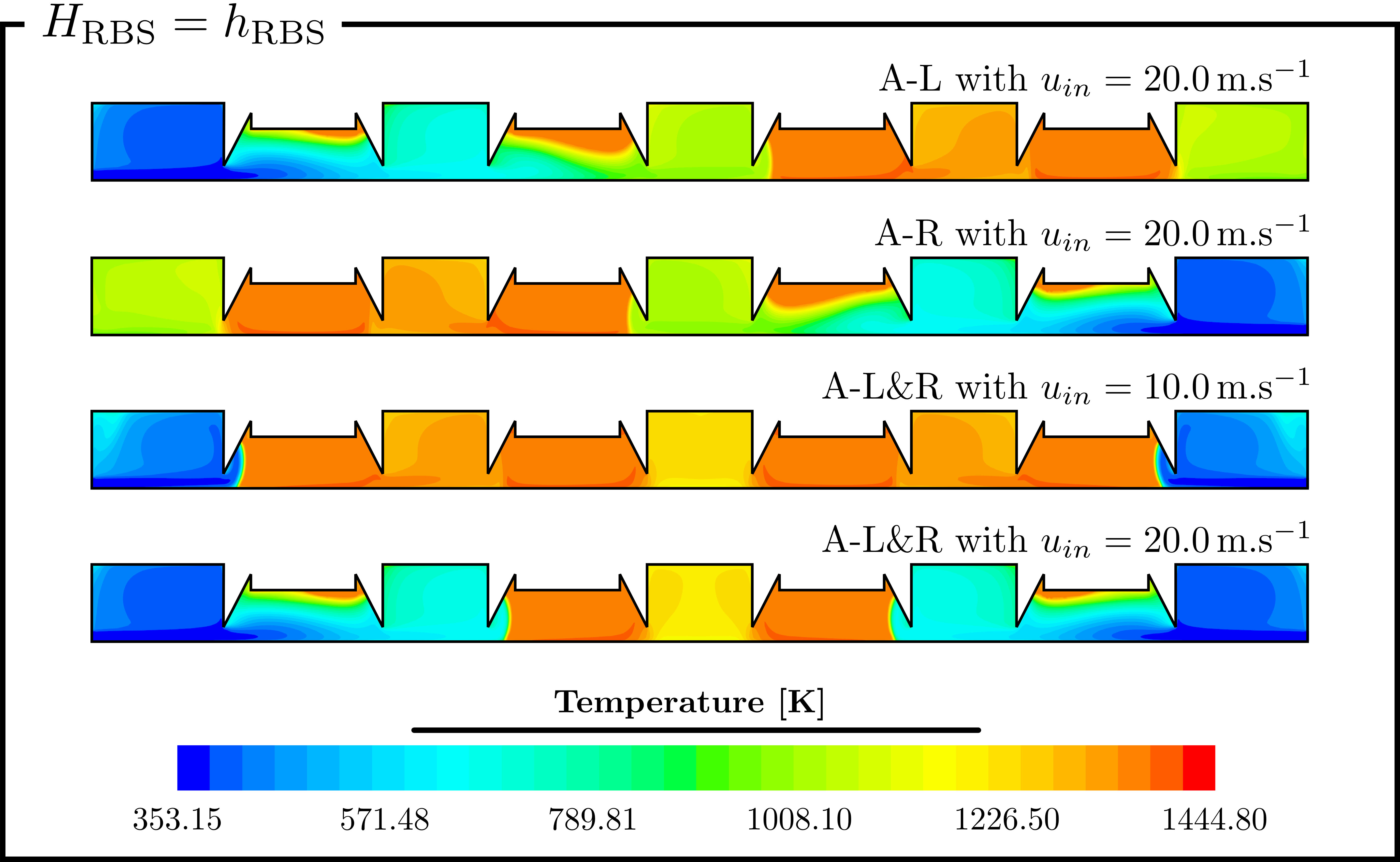

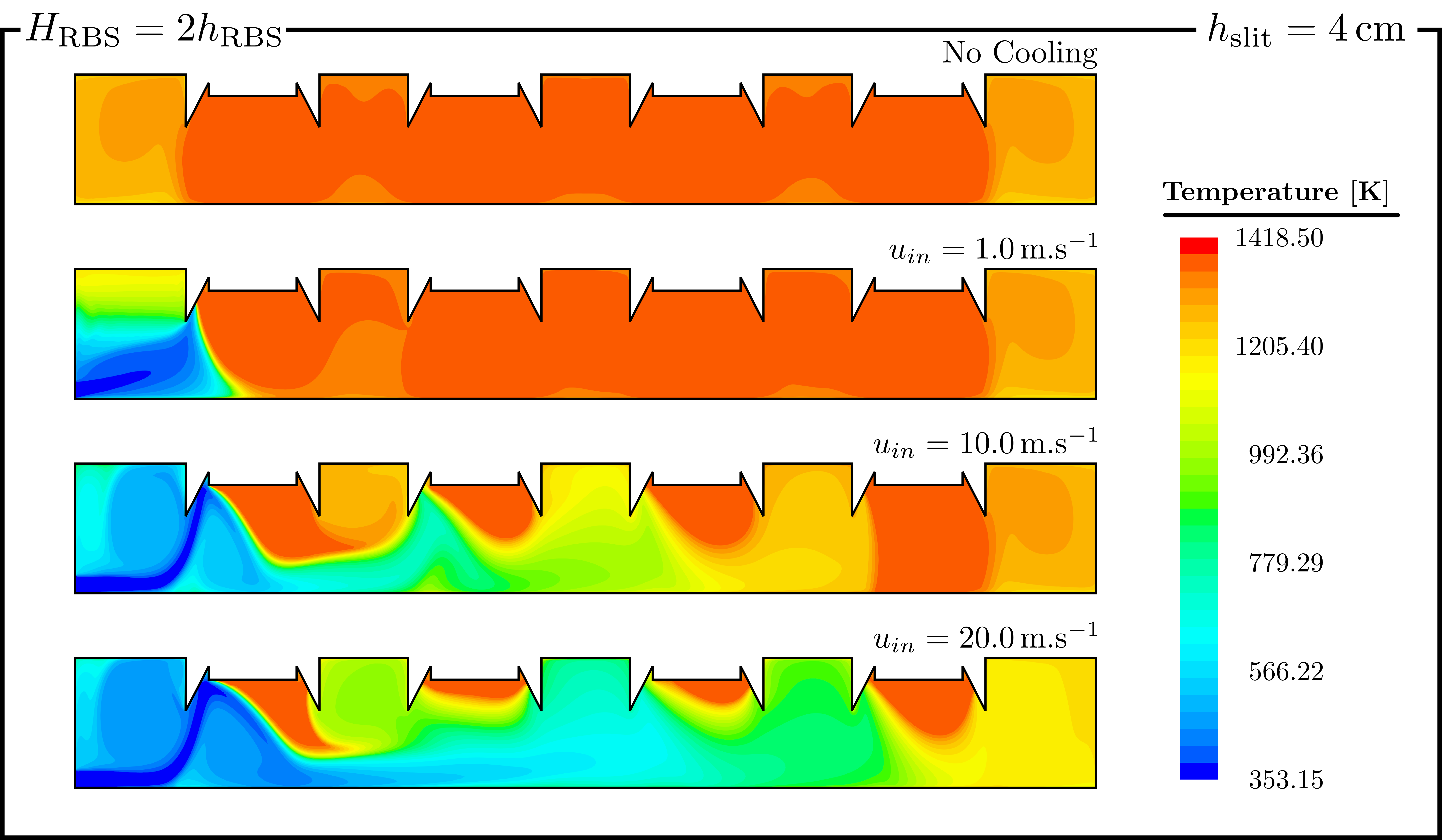

Rodrigo J. F. Neno, Beatriz S. Dias, Jorge E. P. Navalho, and José C. F. Pereira. Numerical Simulation of Heat Removal from a Window Slab Partition of a Radiative Coil Coating Oven. Energies. 15:2080, 2022. [PDF] [BIB] [PUB]

Beatriz S. Dias, Jorge E. P. Navalho, and José C. F. Pereira. Multi-scale modeling and simulation of IR radiative drying for coil coating processes. Drying Technology. 40:3466—3482, 2022. [PDF] [BIB] [PUB]

Jorge E. P. Navalho and José C. F. Pereira. A comprehensive and fully predictive discrete methodology for volumetric solar receivers: application to a functional parabolic dish solar collector system. Applied Energy. 267:114781, 2020. [PDF] [BIB] [PUB]

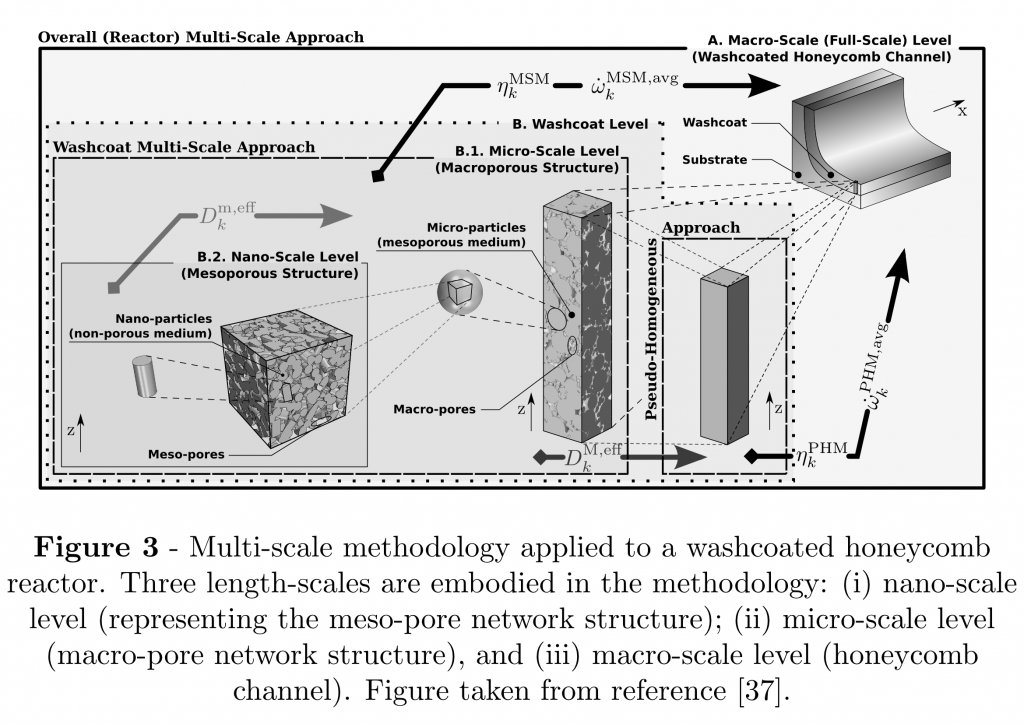

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. Multiscale modeling of methane catalytic partial oxidation: From the mesopore to the full-scale reactor operation. AIChE Journal. 64:578–594, 2018. [PDF] [BIB] [PUB]

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. A methodology for thermal analysis of complex integrated systems: Application to a micro-CHP plant. Applied Thermal Engineering. 112:1510–1522, 2017. [PDF] [BIB] [PUB]

J. E. P. Navalho, J. M. C. Pereira, and J. C. F. Pereira. Multi-scale modeling of internal mass diffusion limitations in CO oxidation catalysts. Defect and Diffusion Forum. 364:92–103, 2015. [PDF] [BIB] [PUB]

J. M. C Pereira, J. E. P. Navalho, A. C. G. Amador, and J. C. F. Pereira. Multi-scale modeling of diffusion and reaction-diffusion phenomena in catalytic porous layers: Comparison with the 1D approach. Chemical Engineering Science. 117:364–375, 2014. [PDF] [BIB] [PUB]

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. Conical-shaped foam reactors for catalytic partial oxidation applications. International Journal of Hydrogen Energy. 39:3666–3680, 2014. [PDF] [BIB] [PUB]

Jorge E. P. Navalho, José M. C. Pereira, Ana R. Ervilha, and José C. F. Pereira. Uncertainty quantification in the catalytic partial oxidation of methane. Combustion Theory and Modelling. 17:1067–1095, 2013. [PDF] [BIB] [PUB]

J. E. P. Navalho, I. Frenzel, A. Loukou, J. M. C. Pereira, D. Trimis, and J. C. F. Pereira. Catalytic partial oxidation of methane rich mixtures in non-adiabatic monolith reactors. International Journal of Hydrogen Energy. 38:6989–7006, 2013. [PDF] [BIB] [PUB]

White Papers

Technical reports

Beatriz Dias, Rodrigo Neno, J. E. P. Navalho, and J. C. F. Pereira. D6.4: Detailed CFD simulation of curing furnace section. ECCO Project. July 2020. [PDF] [BIB]

Rodrigo Neno, Beatriz Dias, J. E. P. Navalho, and J. C. F. Pereira. D6.3: Detailed CFD simulation of radiant heating section. ECCO Project. July 2020. [PDF] [BIB]

J. E. P. Navalho, J. P. B. Lourenço, J. M. C. Pereira, and J. C. F. Pereira. D5.4: Preliminary design and CFD simulation of radiant heating section. ECCO Project. April 2019. [PDF] [BIB]

J. Navalho, J. M. C. Pereira, J. C. F. Pereira, G. Vourliotakis, Ch. Keramiotis, G. Skevis, M. Founti, and Ciprian Chisega-Negrilã. D3.3: Report on results from case studies for biogas fuel utilization at the FC-District unit. FC-district Project. February 2013. [PDF] [BIB]

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. D8.6: Virtual-tool-box for heat transfer integration components. FC-district Project. October 2013. [PDF] [BIB]

S. Fernandes and J. Navalho. D3.1.3: Equipment list and summary sheets, technical layout and evaluation of CPOx reformer (Annex 2). FC-district Project. September 2011. [PDF] [BIB]

Pedagogical Support Material for Students

Slides for the Computational Laboratories of the “Heat Transfer” course (Graduate course of Mechanical Engineering and Aerospace Engineering curricula) – Fall 2019:

Computational Laboratory 1 — Heat Transfer from Extended Surfaces; [PDF]

Computational Laboratory 2 — One Dimensional, Transient Conduction; [PDF]

Computational Laboratory 3 — Forced convection on a flat plate; [PDF]

Computational Laboratory 4 — Heat Exchangers. [PDF]

List of problems for practical classes of the “Thermal Equipments” course (Graduate course of Mechanical Engineering and Energy Engineering and Management curricula) – Spring 2015. [PDF]

Project Reports of Graduate Courses

Métodos Computacionais em Electromagnetismo (Curso de Estudos Avançados do Programa Doutoral em Engenharia Mecânica) – Aplicação do método dos elementos finitos a problemas do campo em electromagnetismo, Julho 2018. [PDF]

Ensino e Divulgação Científica (Curso de Estudos Avançados do Programa Doutoral em Engenharia Mecânica) – Relatório de Actividades de Ensino: Experiência e Resultados, Julho 2018. [PDF]

Theses

Jorge Emanuel Pereira Navalho. Multi-Scale Modeling and Simulation of Heterogeneous Catalytic Reactors. Ph.D. Thesis. Instituto Superior Técnico, Universidade de Lisboa, February 2020. [BIB]

Jorge Emanuel Pereira Navalho. Modeling and Simulation of Catalytic Partial Oxidation in Monolith Reactors. M.Sc. Thesis. Instituto Superior Técnico, Universidade de Lisboa, July 2013. [BIB]

Conferences

B. A. C. Barata, J. E. P. Navalho, and J. C. F. Pereira. Numerical study of heat transfer characteristics of impinging jets on a steady or moving plate. 17th International Heat Transfer Conference (IHTC-17). 14–18 August, 2023, Cape Town (South Africa).

B. A. C. Barata, B. S. Dias, J. E. P. Navalho, M. Schneider, P. Weinbrecht, C. Weis, D. Trimis, and J. C. F. Pereira. Numerical investigation of an innovative furnace concept for coil coating process. 13th European Conference on Industrial Furnaces and Boilers (INFUB-13). 19–22 April, 2022, Algarve (Portugal).

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. A multi-scale approach for modeling heterogeneous reactions in porous catalysts. 4.º Encontro de Jovens Investigadores do LAETA (4EJIL). 9–10 November, 2017, Covilhã (Portugal)

J. E. P. Navalho, J. M. C. Pereira, and J. C. F. Pereira. Effective diffusivity evaluation in catalytic porous layers: A multi-scale approach. 10th International Conference on Diffusion in Solids and Liquids: DSL 2014. DSL 303. 23–27 June, 2014, Paris (France)

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. Parametric and model uncertainty propagation in catalytic partial oxidation. 11th World Congress on Computational Mechanics (WCCM XI), 6th European Conference on Computational Fluid Dynamics (ECFD VI). 20–25 July, 2014, Barcelona (Spain)

Jorge E. P. Navalho, José M. C. Pereira, and José C. F. Pereira. Modeling analysis of methane catalytic partial oxidation as a route to produce hydrogen rich mixtures. IV Conferência Nacional em Mecânica de Fluidos, Termodinâmica e Energia (MEFTE 2012). 28–29 Maio, 2012, Lisboa (Portugal) [PDF]

Jorge E. P. Navalho, Miguel A. A. Mendes, José M. C. Pereira, and José C. F. Pereira. Análise em regime estacionário da oxidação parcial catalítica de metano em ródio. X Congresso Ibero-Americano em Engenharia Mecânica (CIBEM10). 4–7 September, 2011, Porto (Portugal) [PDF]

Projects

EU-funded projects: participation

1. ECCO Project (2017-2021)

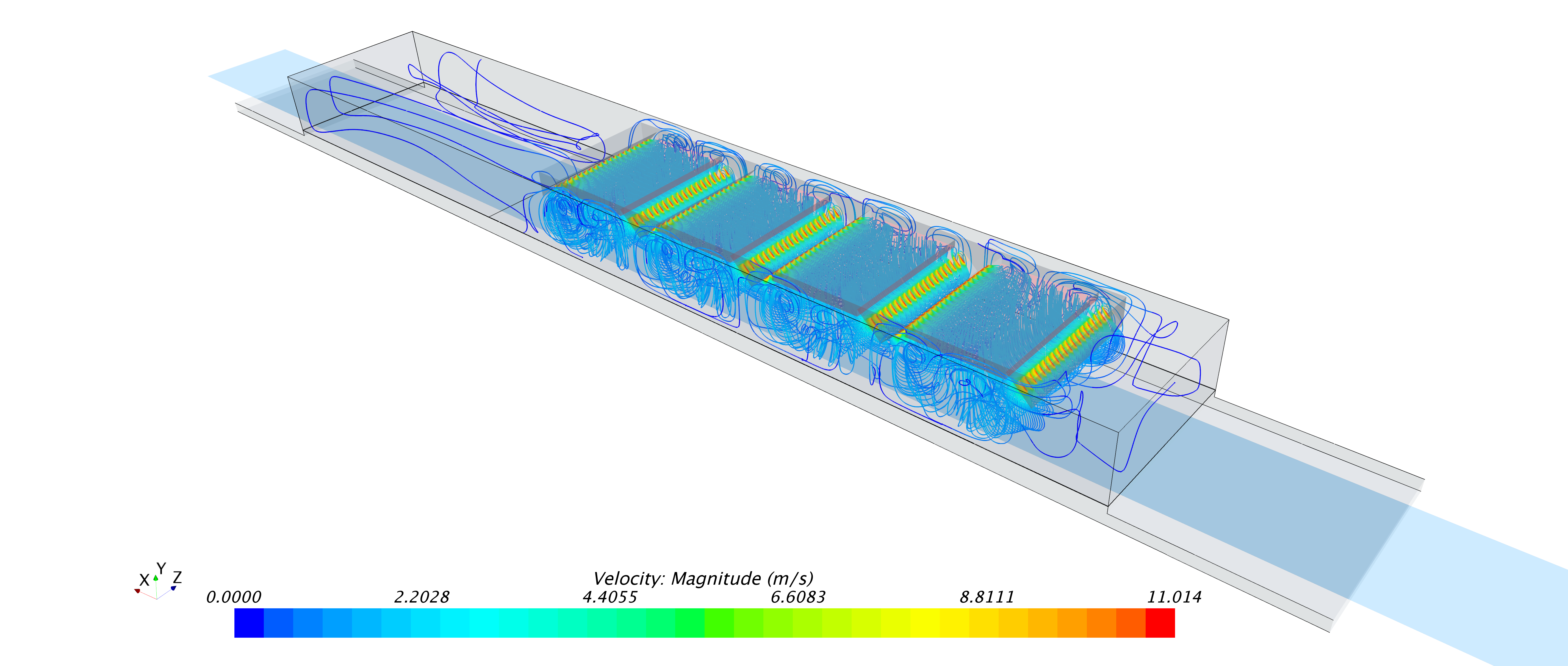

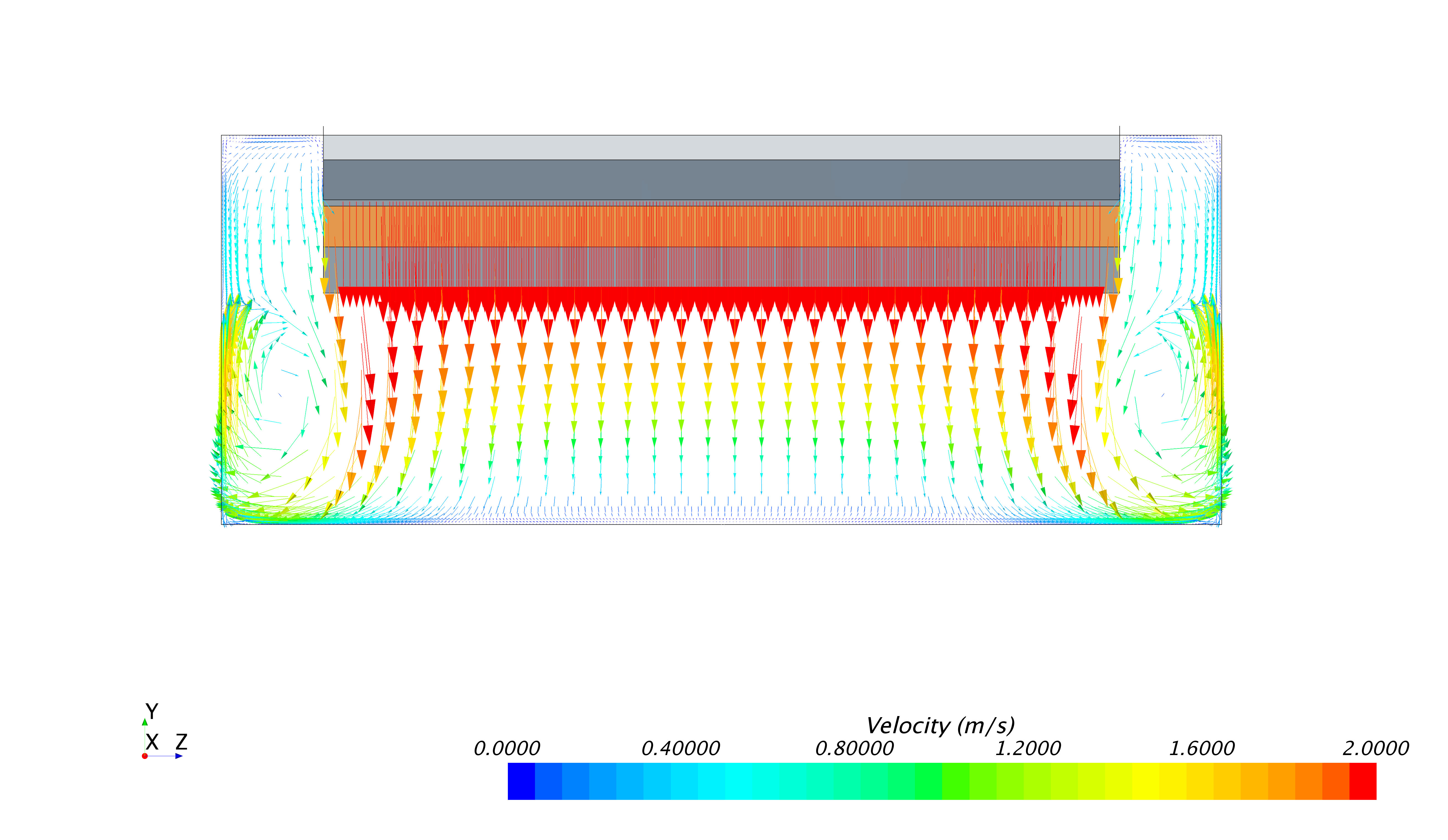

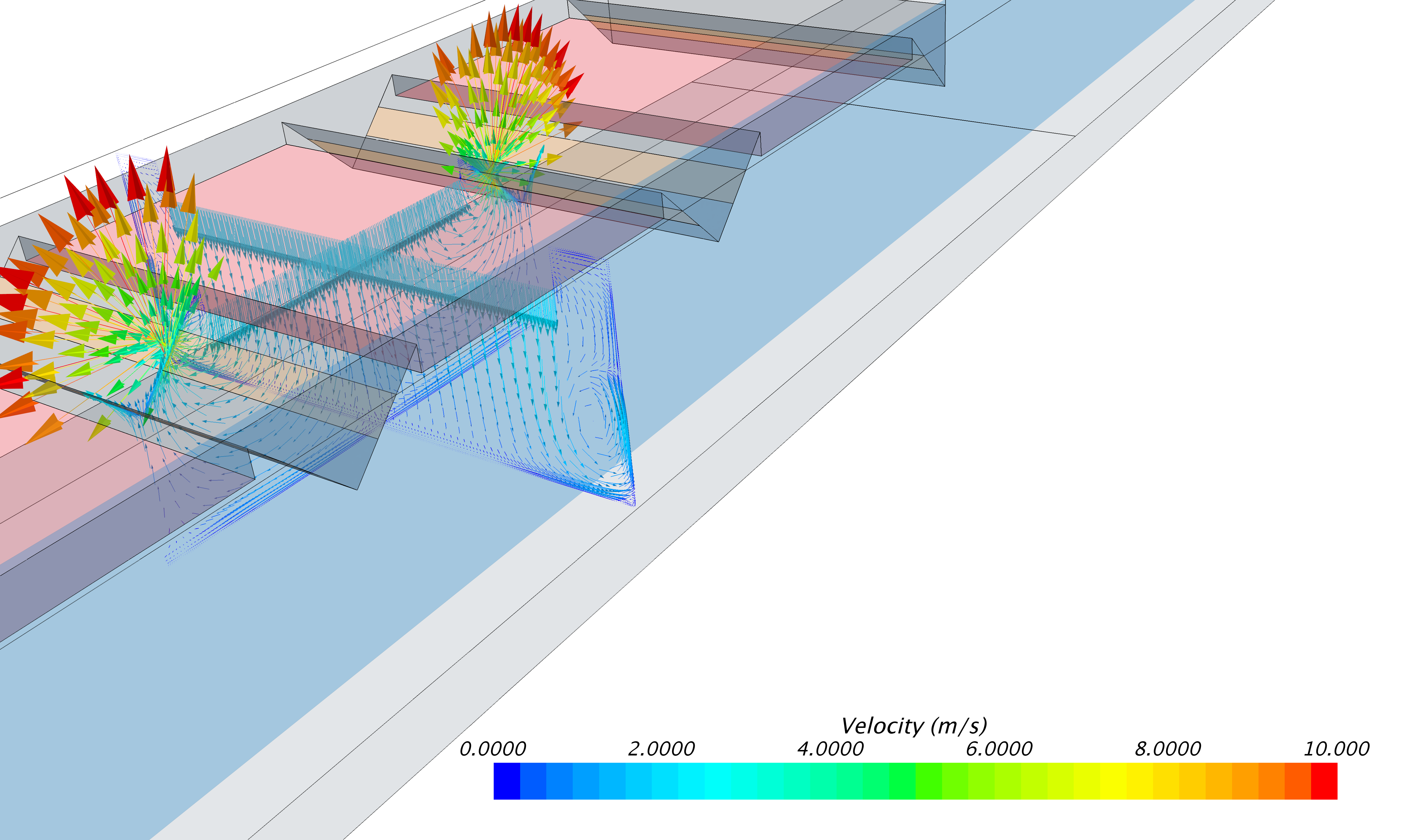

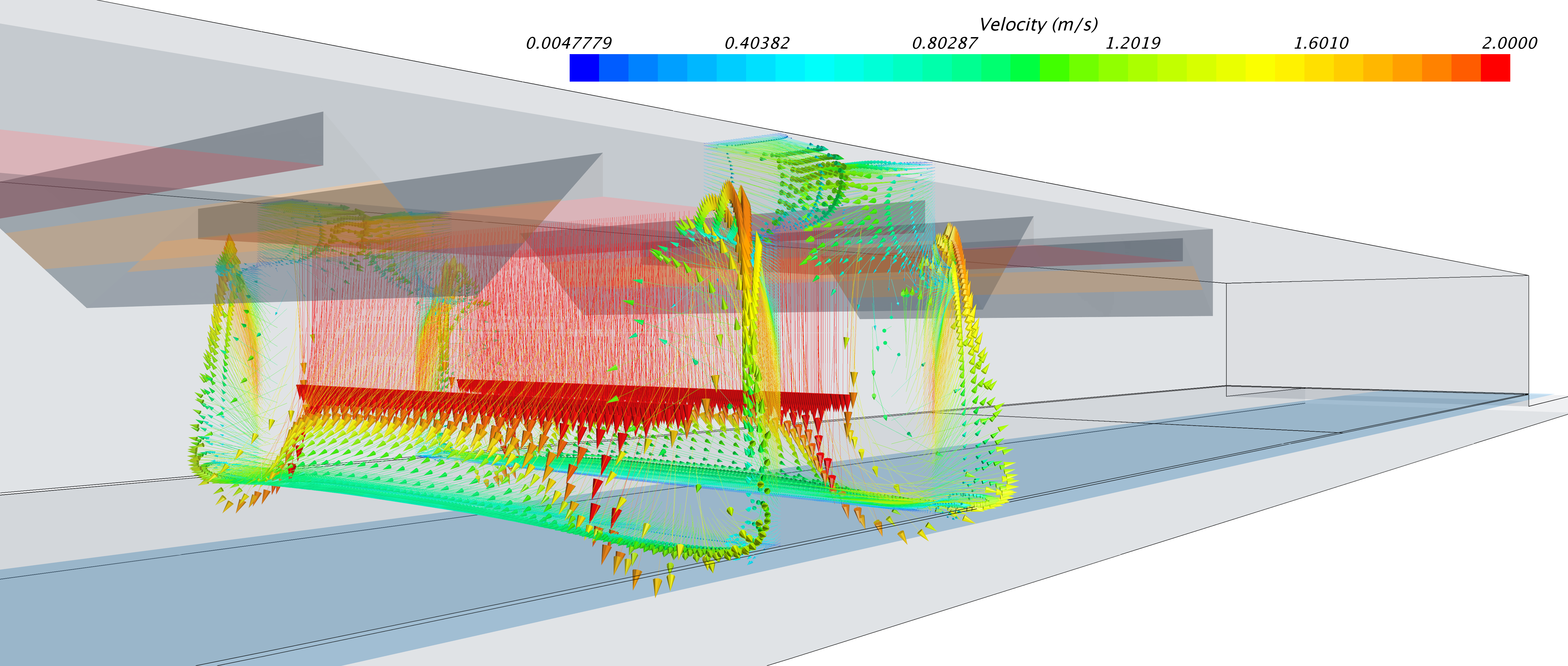

The ECCO project aims at developing an innovative furnace for drying and curing organic paints that are commonly applied on the surface of metal coils for protective and decorative purposes. The proposed coating drying/curing concept does not rely on the traditional convective air drying technology. Instead, the energy required for driving the overall thermochemical processes in the coating is delivered to it through radiative heat transfer from radiant burners that are fed with previously evaporated solvents. To comply with such requirements, the ECCO curing furnace is composed by two main regions that communicate directly with each other exclusively through heat transfer. These regions are herein termed as the radiant burner section (RBS) and curing oven section (COS). The figure provides a simplified representation of the curing furnace concept depicting the furnace main regions and components (identified by the corresponding names) as well as the relative position between them.

The COS is continuously fed with a coated metal strip. The RBS provides the heat source – IR- radiation emitted from radiant porous burners – to execute the coating drying and curing processes that take place at the COS. Along the residence time of the coated coil within the COS, the coating (wet paint) needs to be dried and cured to meet the required standards. The released toxic solvent species are collected from the COS and guided towards the radiant burners feeding system in order to, simultaneously, incinerate the solvent species and decrease or eliminate the fraction of natural gas required. The radiant burners are placed at the ceiling of the RBS to promote high radiative heat transfer rates from the emission source (porous media) to the coated metal stip. These burners are developed to maximize the radiant power fraction over the advective heat transfer contribution from the released combustion energy. In order to guarantee the separation between the atmospheres of both sections while simultaneously supporting the radiative heat transfer coupling between sections, a window made out of a highly transparent glass is applied in between both regions.

2. FC-District Project (2010-2014)

The overall objective of the FC-DISTRICT project is to optimize and implement an innovative energy production and distribution concept for sustainable and energy efficient refurbished and/or new “energy autonomous” districts exploiting decentralized co-generation coupled with optimized building and district heat storage and distribution network. The concept is based on dynamic heat exchange between the building(s) (fitted with Solid Oxide Fuel Cells (SOFCs) for energy production collaborating with improved thermal storage and insulation building systems), the distribution system (optimized piping and district heating with or without a heat buffer) and the consumer (new business and service models), aiming to achieve energy balance at district level. Advanced insulation materials will be developed and implemented for the improvement of building and pipe thermal response. The energy reduction will originate from improved efficiency and cost effective high temperature (SOFC), to act as micro heat and power cogeneration (μ-CHP) systems providing demand-flexible electricity and heat to the building and district, coupled with optimised energy and power distribution networks that will optimally control heat storage at building and/or district level. FC-DISTRICT integrates a proven innovative mid-term energy technology (SOFC) with heat management at building and district level (building thermal storage coupled with intelligent distribution networks) to serve the consumer needs for economy-ecology-sustainability. It introduces a new paradigm in energy efficiency by developing materials, technologies, methodologies and systems specifically intended for integration at district level.

1. FCT Project – “Multi-scale prediction of methane reforming under microwave heating”. Submitted on January 2015

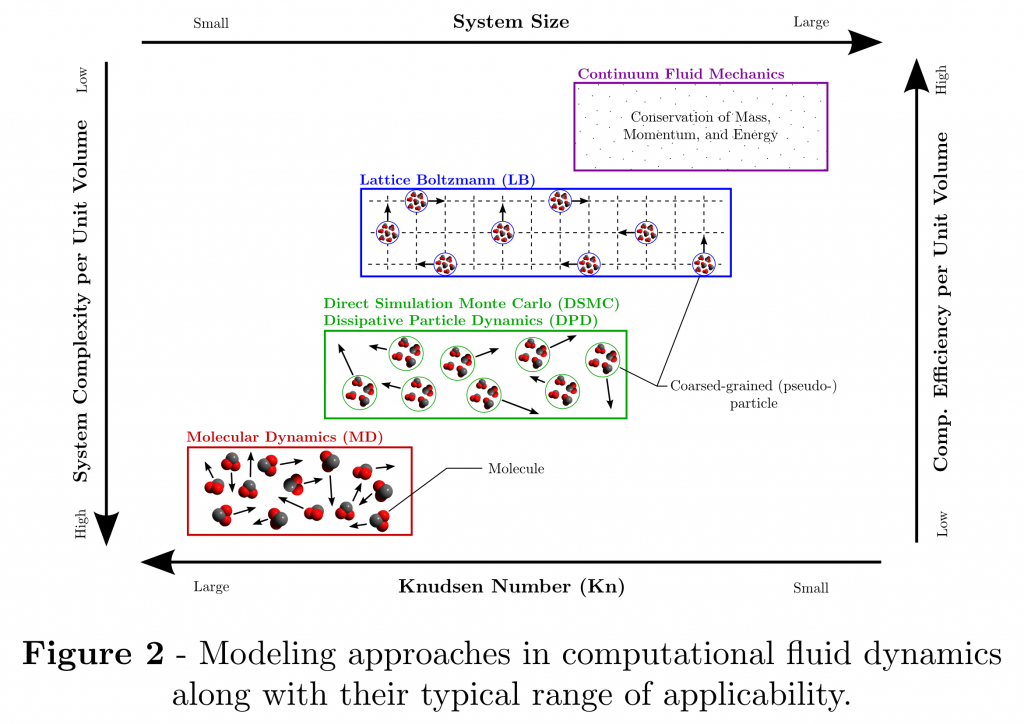

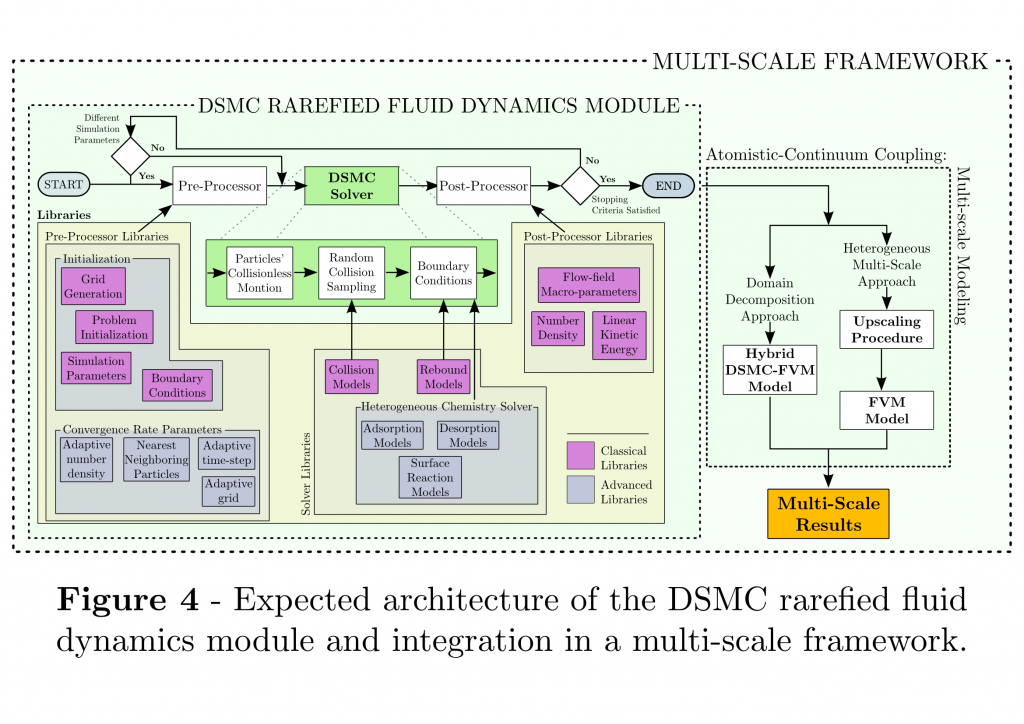

2. FCT Project – “An innovative hybrid particle-continuum method for multi-scale transport in porous media”. Submitted on May 2017